Automation in Semi-Trailer Axle Production

Release time:

Sep 15,2025

Source:

In recent years, the transportation industry has witnessed a significant transformation, primarily driven by advancements in technology. One of the most impactful developments is the integration of automation equipment in the production of semi-trailer axles. This evolution not only enhances operational efficiency but also elevates product quality and consistency in manufacturing processes.

Semi-trailer axles are critical components in the transportation sector, serving as the backbone of heavy-duty trailers. As demand for these essential parts grows, manufacturers are turning to automation equipment to streamline their production lines. The implementation of automated solutions offers several advantages that are redefining industry standards.

1. Increased Production Efficiency

The primary benefit of utilizing automation equipment in semi-trailer axle production is the significant increase in efficiency. Automated machinery can operate continuously, reducing downtime associated with manual labor. This allows manufacturers to meet rising demand without compromising quality. The ability to produce axles at a higher volume translates directly to enhanced profitability, as companies can capitalize on economies of scale.

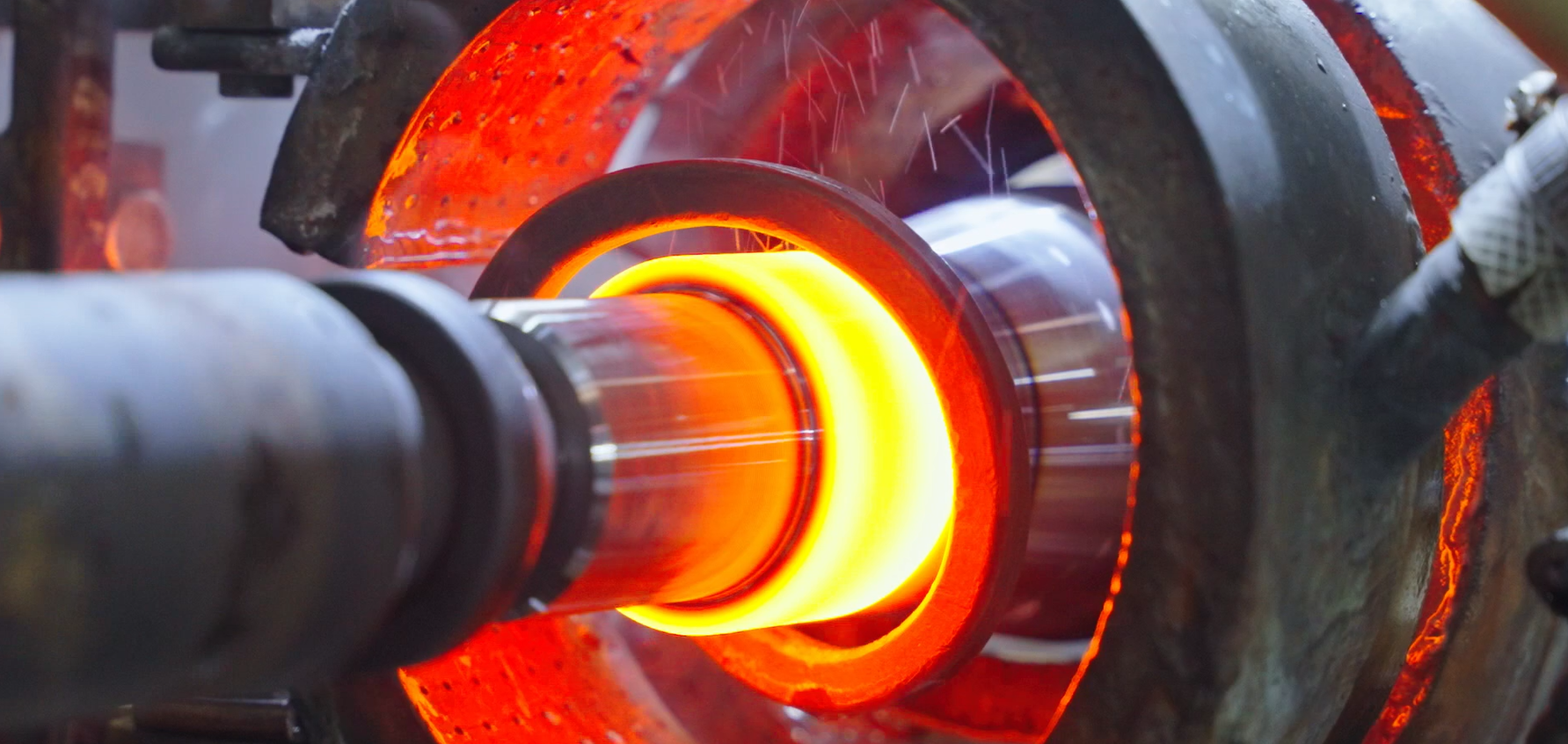

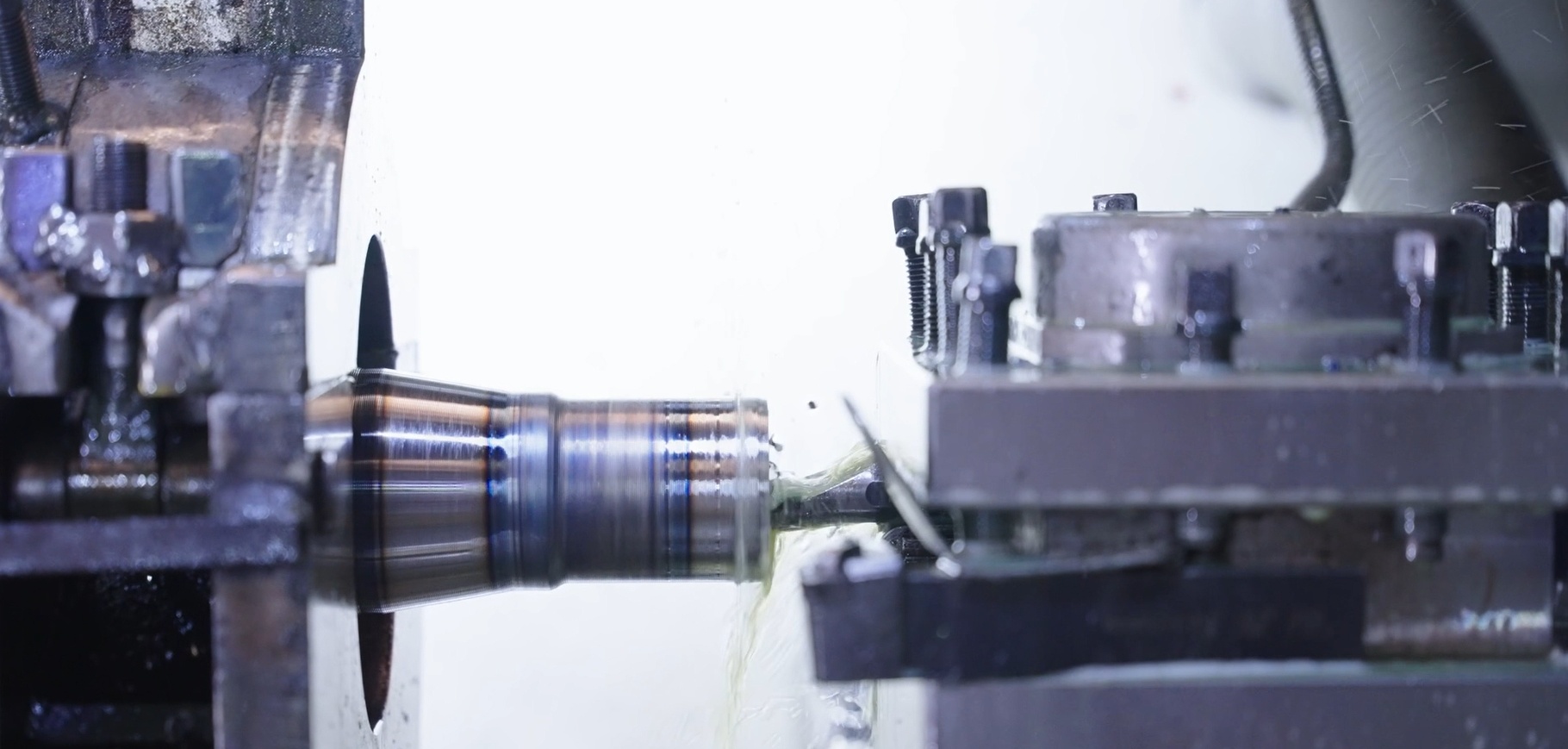

2. Enhanced Precision and Quality Control

Automation equipment is designed to perform tasks with high precision. In the production of semi-trailer axles, precision is critical, as even the smallest deviation can lead to safety issues and increased wear and tear on vehicles. Automated systems, such as CNC machines and robotic welders, ensure that each axle meets stringent quality standards. This level of consistency minimizes defects and rework, leading to reduced material wastage and lower overall production costs.

3. Improved Worker Safety

The integration of automation equipment also contributes to a safer working environment. By automating hazardous tasks such as welding and heavy lifting, manufacturers can protect their workforce from potential injuries. As a result, companies can experience reduced insurance costs and improved employee morale, as workers can focus on more strategic roles that require critical thinking and problem-solving skills.

4. Flexibility and Adaptability

Modern automated systems offer remarkable flexibility. Manufacturers can easily reprogram machines to accommodate different axle designs or production runs, allowing for rapid scalability in response to market demands. This adaptability ensures that businesses can stay ahead of competitors by quickly adjusting to new trends or customer requirements without significant downtime or investment.

5. Data-Driven Insights

The incorporation of automation equipment also allows for the collection of valuable data throughout the production process. By utilizing advanced analytics and IoT technologies, manufacturers can gain insights into production efficiency, machine performance, and maintenance needs. This data-driven approach enables continuous improvement, optimizing operations and leading to better decision-making processes.

Conclusion

In conclusion, the application of automation equipment in the production of semi-trailer axles represents a paradigm shift in the manufacturing landscape. With increased production efficiency, enhanced precision, improved worker safety, and greater flexibility, companies are well-positioned to meet the growing demands of the transportation industry. As we move forward, the continued investment in automation technologies will undoubtedly shape the future of semi-trailer axle production, driving innovation and sustainability while maintaining the highest standards of quality. For manufacturers looking to stay competitive, embracing automation is no longer just an option; it is essential for success.

Related

Sep 26,2025

Understanding the Mechanics of Disc Brakes: A Comprehensive Guide

Dive into the workings of disc brakes, exploring their essential role in vehicle safety and performance.

Sep 25,2025

The Unsung Hero: Understanding the Disc Brake in Modern Vehicles

Explore the intricacies of disc brakes, their functions, benefits, and why they're essential for your vehicle.

Sep 15,2025

Automation in Semi-Trailer Axle Production

The integration of automation equipment in the production of semi-trailer axles has significantly transformed the transportation industry. Automation enhances operational efficiency, enabling continuous production and reducing downtime, which helps manufacturers meet growing demand without sacrificing quality. This leads to increased profitability by capitalizing on economies of scale. Furthermore, automated systems, such as CNC machines and robotic welders, ensure high precision in axle production, adhering to strict quality standards and minimizing defects. This precision reduces material wastage and lowers overall production costs. Additionally, automation improves worker safety by taking over hazardous tasks, creating a safer working environment. Overall, the application of automation equipment is redefining industry standards in the manufacturing of semi-trailer axles, enhancing efficiency, quality, and safety.

Dec 19,2025

The Unsung Hero of Transportation: The German Type Axle

Discover the significance of the German Type Axle in various industries and its impact on transportation.

Dec 14,2025

The Rise of the German Type Axle: A Game Changer in the Industry

Discover the latest trends and innovations surrounding the German Type Axle in the automotive industry.

Dec 09,2025

Exploring the Inner Workings of the German Type Axle

Discover the fascinating workings of the German Type Axle and its impact on modern engineering.